As a core component of peristaltic pumps, tubing plays a critical role in determining fluid safety and pump longevity. The choice of tubing material directly affects performance and durability. Different applications require different tubing types. This article introduces common peristaltic pump tubing options and their characteristics to help businesses make informed decisions.

Silicone Tube: Preferred for Pharmaceutical and Food Industries

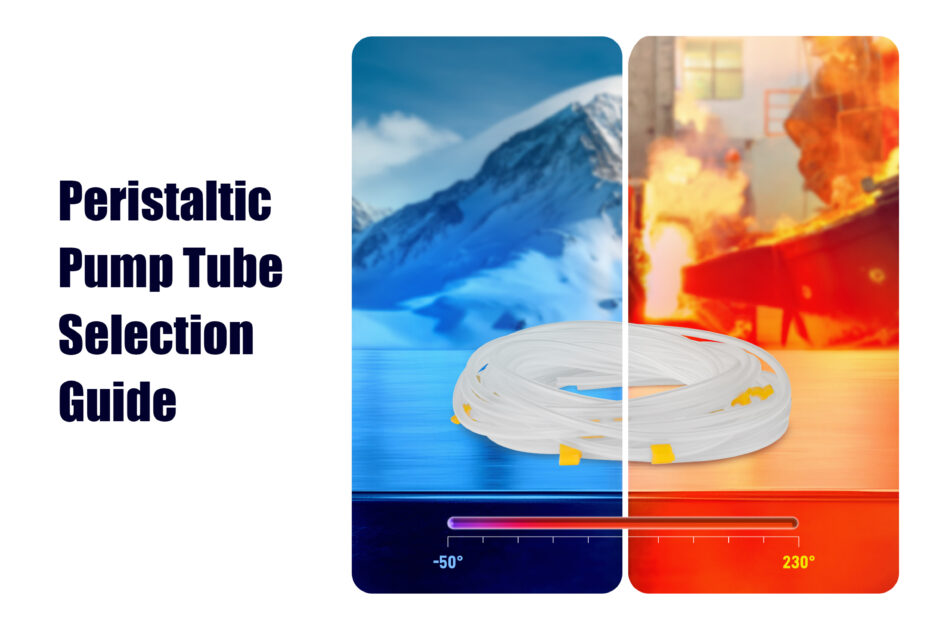

Silicone tubing offers excellent flexibility and high-temperature resistance, making it ideal for applications with strict hygiene requirements such as pharmaceuticals and food processing.

Advantages:

• Wide temperature range: -50°C to 200°C

• Non-toxic and odorless: Complies with FDA and USP standards

Limitations:

• Poor chemical resistance; not suitable for strong acids or bases

Chemical Tube: Ideal for Corrosive Fluid Transfer

Chemical tubing is designed for handling aggressive chemicals, offering superior resistance to acids, bases, and solvents.

Features:

• Excellent chemical resistance

• High wear resistance for long-term operation

Limitations:

• Lower flexibility; requires careful installation

PharMed Tube: High Durability and Biocompatibility

PharMed tubing is widely used in pharmaceutical and biotech industries due to its outstanding fatigue resistance and long service life.

Advantages:

• Superior wear and fatigue resistance

• Biocompatible and meets medical standards

Limitations:

• Higher cost compared to standard tubing

Viton Tube: Combines Heat and Chemical Resistance

Made from fluoroelastomer, Viton tubing is suitable for high-temperature and highly corrosive environments.

Features:

• Excellent heat resistance up to 200°C

• Resistant to oils and solvents

Limitations:

• Less flexible and relatively expensive

A-60-F and A-60-G Tubes: Industrial-Grade Performance

These thermoplastic elastomer tubes are widely used in industrial fluid transfer.

A-60-F: Strong chemical resistance for corrosive liquids

A-60-G: Exceptional abrasion resistance for high-frequency operation

Both offer good flexibility and durability, making them ideal for demanding industrial applications.

Selection Tips

When choosing peristaltic pump tubing, consider:

• Fluid properties: Corrosiveness, food-grade requirements

• Operating conditions: Temperature and pressure

• Usage frequency:Continuous operation requires fatigue-resistant tubing

• Cost and maintenance: Balance performance with budget

Conclusion

Selecting the right peristaltic pump tubing ensures safe fluid transfer and extends equipment life. Businesses should choose silicone, Chemical, PharMed, Viton, or A-60 series tubing based on their specific application needs to maintain efficient, stable, and secure operations.