Today, let’s focus on the heart of every pharmaceutical product—the Active Pharmaceutical Ingredient (API). This is the core component that delivers the drug’s therapeutic effect.

Why Is the API So Important?

Because the drug’s efficacy and safety depend on the choice and precise dosage of the API. Only when the API meets quality standards can the medicine be effective; otherwise, it may compromise treatment outcomes or even pose safety risks. In short, the API is the foundation of drug development and manufacturing, allowing no margin for error.

API vs. Drug Product

- The API provides the therapeutic “power”, while the finished drug ensures safe and convenient administration.

- Without the API, a drug loses its efficacy; without a dosage form, the API cannot be safely or effectively delivered.

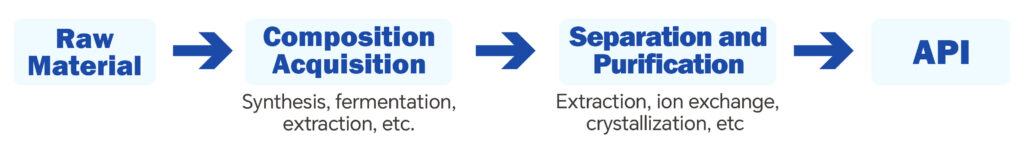

How Is an API Manufactured?

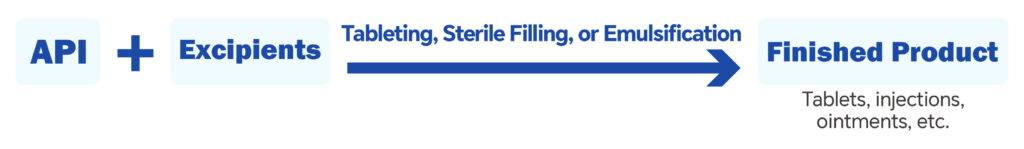

To turn an API into a usable medicine, it must then undergo formulation processing, including:

API production is strictly regulated by health authorities around the world and must be carried out under GMP-compliant conditions to ensure drug quality and safety.

Why API Production Depends on Peristaltic Pumps

API processes demand high precision, purity, sterility, and process stability. Peristaltic pumps work by cyclically compressing and releasing flexible tubing with rotating rollers, allowing the fluid to contact only the tube’s inner wall—ideal for sterile, single-use flow paths and fast changeovers. Their low shear, accurate dispensing, and gentle transfer characteristics make them particularly suitable for cell- and protein-sensitive operations, making peristaltic pumps essential across the entire API production chain.

Typical Peristaltic Pump Applications in API Production

Upstream: Synthesis / Fermentation / Extraction

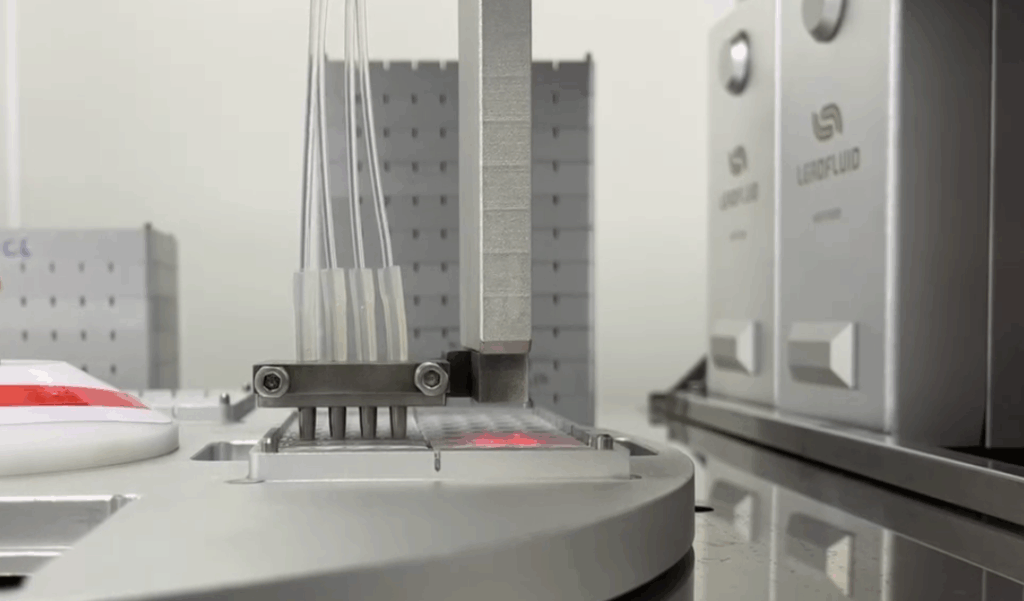

* Lead Fluid FT1505 pump head applied to bioreactors

Bioreactor shown is not a Lead Fluid product; for demonstration only

- Precise Feeding and Titration

Used for quantitative addition of raw materials, acids/bases, and catalysts, maintaining stable reaction conditions and minimizing side reactions. Can be integrated with pH, mass flow, or weighing systems for closed-loop control, ensuring consistency.

- Sterile Nutrient Addition

In fermentation or cell culture, peristaltic pumps provide low-shear, sterile, single-use nutrient or buffer addition, gently maintaining the optimal cell environment.

Key Performance Requirements

▲ High flow accuracy and repeatability

▲ Compatible with single-use or SIP/CIP-resistant tubing

▲ Broad chemical compatibility

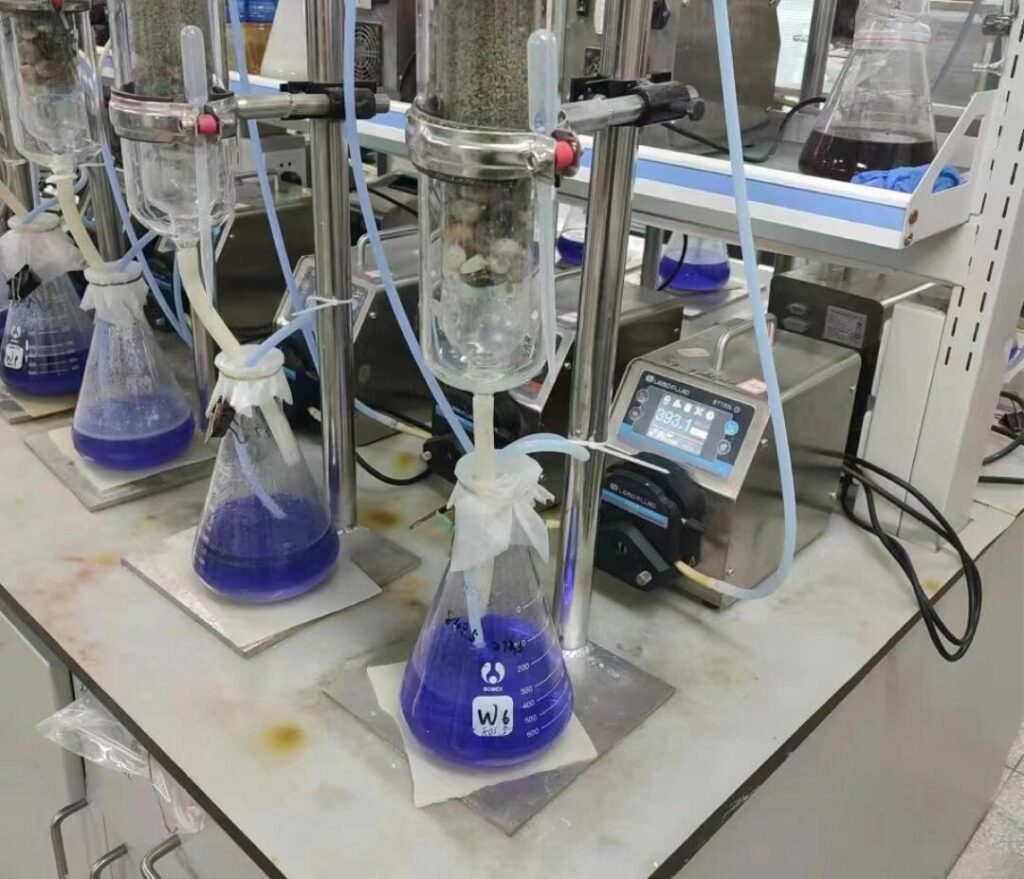

Midstream: Separation and Purification (Chromatography / Filtration / Crystallization)

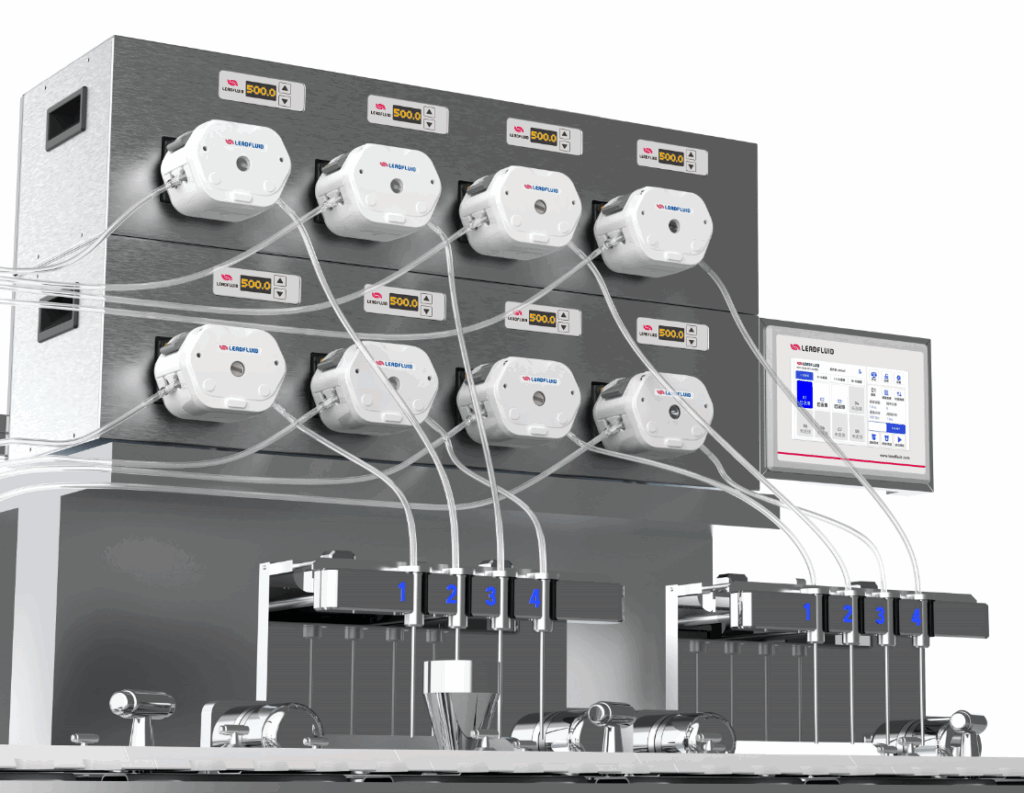

* Lead Fluid pumps integrated into chromatography and filtration systems

- Gentle Transfer

Ensures stable conveyance of fermentation broth or reaction mixtures, avoiding bubbles and protecting proteins or cells from damage.

- Chromatography Feed

Chromatography demands highly stable flow and minimal pulsation. Peristaltic pumps deliver continuous, smooth flows, improving separation efficiency and consistency. - Filtration Systems

Provides controlled inlet flow and pressure, critical for membrane life and batch-to-batch reproducibility.

Key Performance Requirements

▲ Low-pulsation output

▲ Wide flow range, suitable from lab to pilot scale

▲ Resistant to various buffers and solvents

Downstream: Formulation and Filling

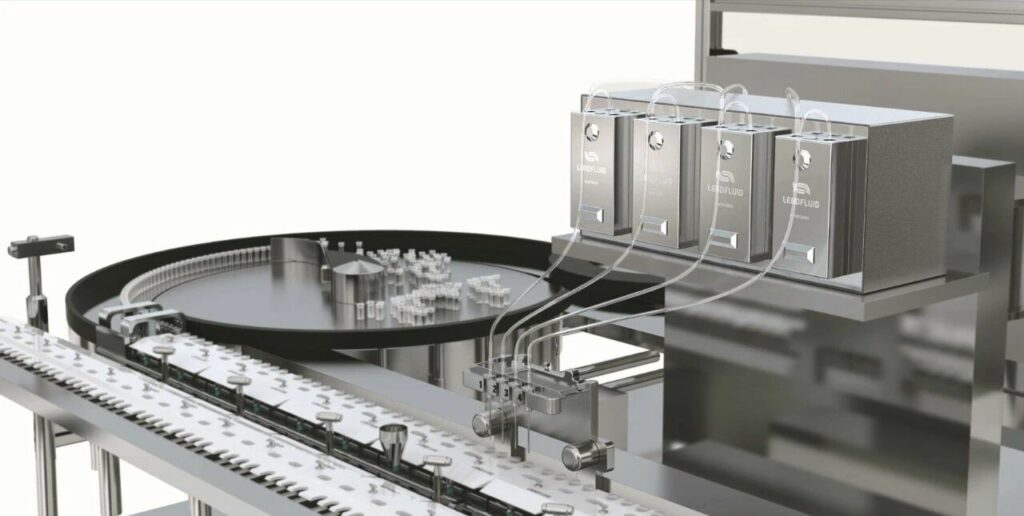

*Lead Fluid WSP3000 used for reagent dispensing

- Intermediate Transfer

Transfers API solutions or suspensions smoothly and cleanly to crystallization or drying equipment.

- Sterile Filling

Peristaltic pumps ensure accurate, sterile, and single-use liquid handling, becoming the core solution for aseptic filling. They minimize contamination risks and human error.

Key Performance Requirements

▲ High dispensing consistency

▲ Clean, easily replaceable flow paths

▲ Compliance with GMP and 21 CFR Part 11 data traceability

Recommended Lead Fluid Products

DS600 Filling System

WSP3000 Micro-liter Peristaltic Pump

High-Protection Series Peristaltic Pumps

Integrated Explosion-Proof Peristaltic Pump

FT1505 Pump Head

DMD15 Pump Head

(For detailed selection guidance, please contact your Lead Fluid representative.)

API production is a complex, precision-driven process built on accuracy and risk control. Lead Fluid has long specialized in micro- and small-flow fluid transfer, staying aligned with evolving regulatory and process standards. We are committed to delivering precise, reliable, compliant, and intelligent fluid solutions—protecting drug quality and safety every step of the way.