In the previous article, we explored the five core design elements of the MF103, uncovering the source of its technical “strength.”

However, technology only reveals its true value when applied to practical scenarios.

Across different industries, fluid transfer faces similar ultimate challenges — how to achieve long‑term stability and precision under harsh physical and chemical conditions. This is not only a performance concern, but also one related to risk control, continuous production, and R&D efficiency.

Today, we focus on biopharmaceutical, laboratory, and industrial applications to understand why the MF103, with its high protection level and precision design, has become a reliable choice for these demanding operations.

Biopharmaceutical

Cleaning, Compliance, and Precision Coexist

Key Challenges

▸ Cleaning Difficulty: Frequent rinsing, wiping, and disinfection — how to prevent moisture ingress and internal damage?

▸ Audit and Misoperation: Multi‑shift operations increase risk of accidental or unauthorized parameter changes.

▸ Cleanliness Requirement: How can the device maintain a “zero particulate shedding” and “easy‑to‑clean” design that won’t become a contamination source?

▸ Precision Stability: Ensuring long‑term consistency during continuous operation.

MF103 Solutions

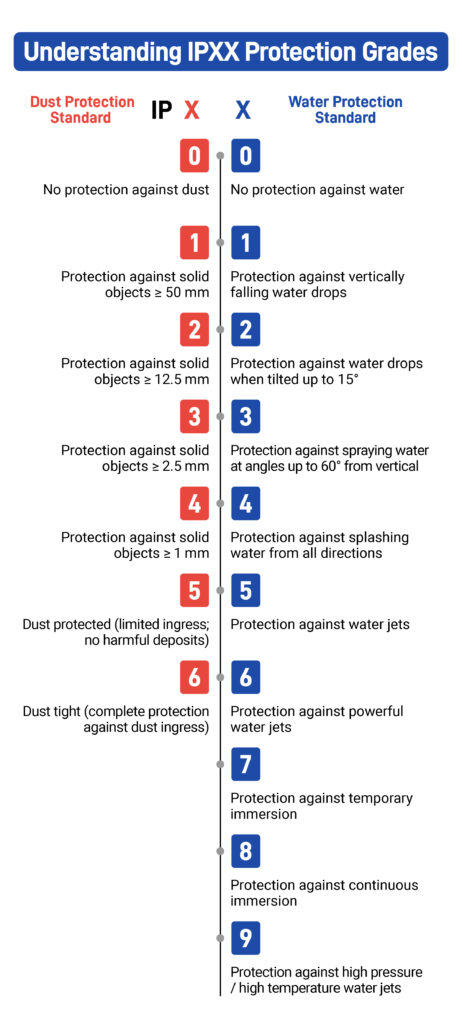

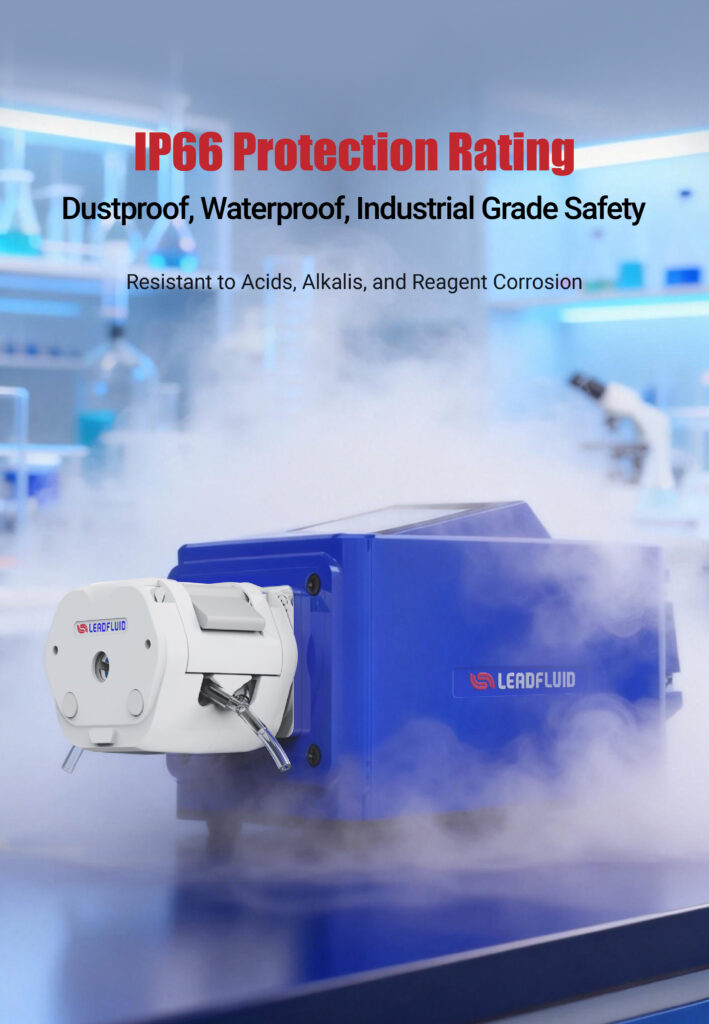

• IP66 Protection Rating: Resistant to direct washing and splashing; internal circuitry remains dry and safe, making validation easier.

• Compliance Shield: Three‑level user authorization reduces misoperation risks and clarifies accountability, supporting audits and traceability.

• Hygienic Design: Die‑cast aluminum housing with anti‑corrosion coating; smooth surfaces, robust structure, no dead corners, easy to clean.

• Stable Control: Precision servo drive ensures accurate and consistent dosing of key fluids such as culture media and buffer solutions.

Laboratory

Corrosion Risk, High‑Frequency Switching, Multi‑User Operation

Key Challenges

▸ Corrosion Risk: Exposure to acidic or alkaline splashes and chemical vapors.

▸ Limited Space: Benchtops are crowded with various instruments — where to place new equipment?

▸ Single‑function Devices: Different experiments require separate pumps, increasing training and setup workload.

▸ Portability: Frequent relocation between workstations or temporary setups.

MF103 Solutions

• Durable and Easy to Maintain: Die‑cast aluminum body with anti‑corrosion coating resists chemical splashes and is easy to wipe clean.

• Compact Footprint: Space‑saving design allows close placement to other instruments without occupying excessive bench space.

• Multi‑Function Capability: Five operating modes (flow rate, volume, time, programming, external control) cover applications from simple transfer to advanced process control, reducing the need for multiple devices and training.

• Flexible Mobility:Compact and lightweight design facilitates quick movement across workstations or projects, enhancing utilization efficiency.

Industrial Settings (e.g., Coating / Dyeing)

Dust, Moisture, and Other Harsh Environments

Key Challenges

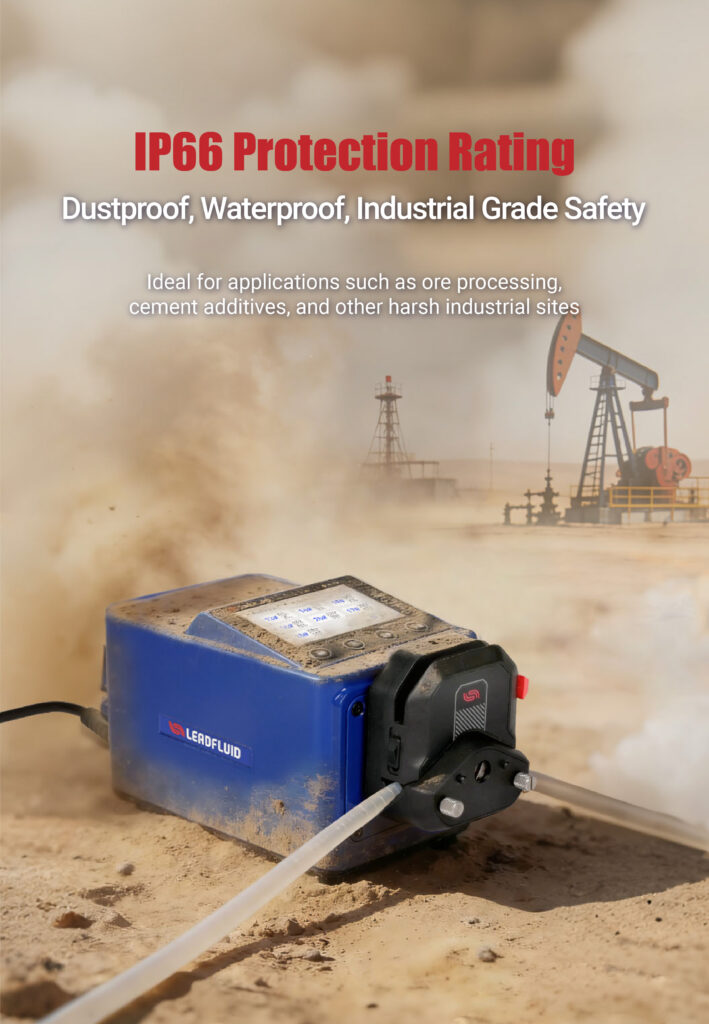

▸ Dust Intrusion: Protection of internal electrical components against fine particulates or fibers.

▸ Moisture Corrosion: Preventing circuit damage and performance drift under humid conditions.

▸ Continuous Operation: Downtime means cost — maintenance intervals must be predictable.

▸ System Integration: Compatibility with existing production lines or control systems.

MF103 Solutions

IP66 Dust and Water Protection: Sealed construction prevents dust and moisture ingress; die‑cast aluminum housing with protective coating enhances durability.

Reliable and Easy to Maintain: Robust one‑piece structure; easy cleaning minimizes unplanned downtime.

System Integration: Supports communication with upper‑level systems, PLCs, or process control systems for seamless production‑line integration.

By combining IP66 protection, integrated die‑cast aluminum housing, anti‑corrosion coating, and precision control, the MF103 truly brings the benefits of “proximity to the process point” — stability, speed, efficiency, and durability —to biopharmaceutical, laboratory, and industrial environments.