Nasal Drug Delivery: The New Frontier of Non-Invasive Administration

Nasal drug delivery—a method where medications are absorbed directly through the nasal cavity—has gained significant attention in recent years for treating asthma, rhinitis, central nervous system diseases, and more. As a cutting-edge approach in modern drug delivery, its advantages include:

- Bypassing First-Pass Effect: Drugs enter the bloodstream directly, avoiding liver metabolism and increasing bioavailability.

- Rapid Onset: Rich vascular network enables quick absorption, ideal for emergency treatments.

- High Patient Compliance: Needle-free, non-invasive, and easy to use, especially suitable for children and the elderly.

Within this trend, single/double-dose nasal sprays (single-dose for fixed one-time use, double-dose for two applications) have become a focus in high-end formulation development due to precise dosing, abuse prevention, and portability.

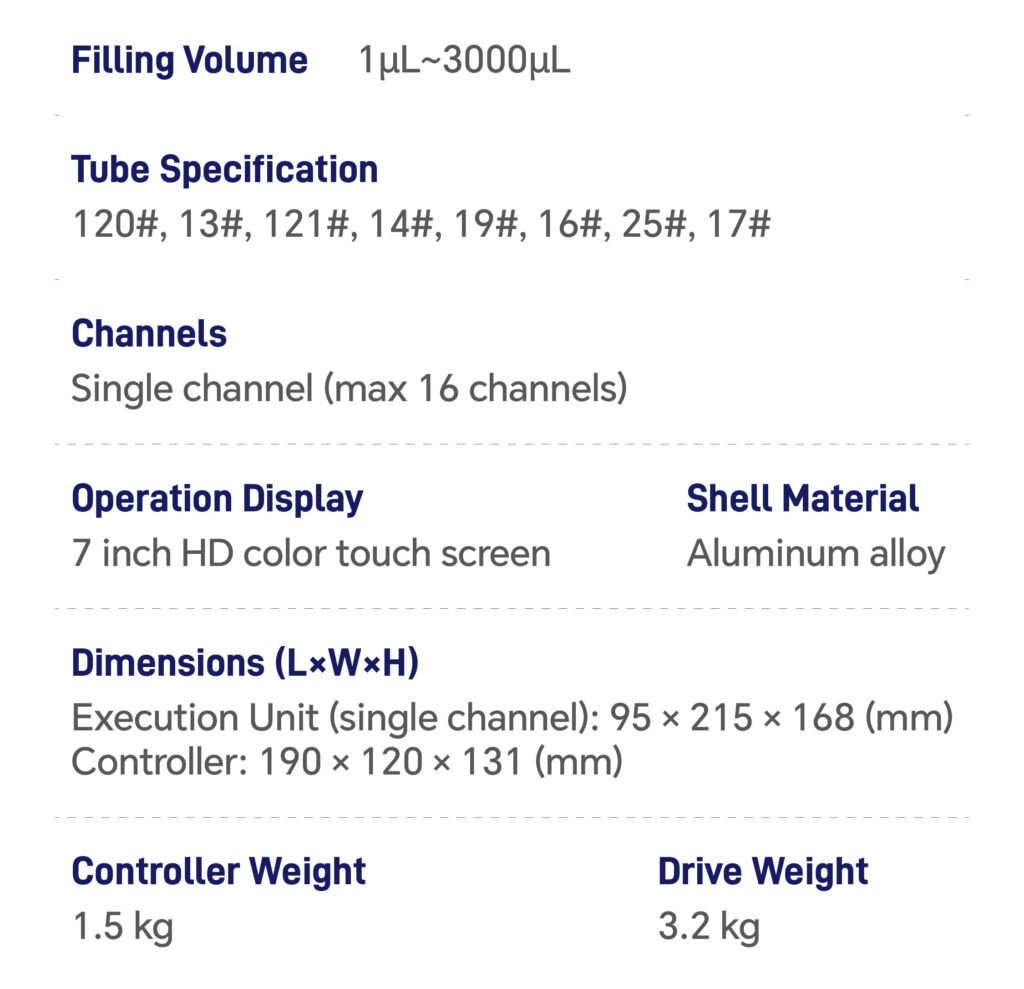

A leading domestic inhalation formulation company integrated Lead Fluid’s WSP3000 Microliter Peristaltic Pump into their new-generation single/double-dose nasal spray filling equipment to enhance accuracy and production consistency.

Precision Is Everything

Nasal spray manufacturing is a tightly regulated process (e.g., GMP) where accuracy is the core challenge:

Regulatory & Process Standards

Content Uniformity (CU) requires each unit’s drug volume to remain stable within strict limits, demanding long-term equipment stability.

Microscale Amplification Effects

Dosing volumes of 50–100 μL magnify even minor errors into significant concentration deviations.

Complex Formulations & Sterility Requirements

Solutions, suspensions, or sensitive biologics require gentle, low-shear handling under sterile conditions.

Filling directly impacts medication safety and efficacy, especially for narrow-therapeutic-window drugs (e.g., vaccines). Solutions must simultaneously address precision, consistency, and sterility.

Six Advantages of the WSP3000

Addressing the challenges above, Lead Fluid’s WSP3000 Microliter Peristaltic Pump delivers systematic solutions through precision-engineered design principles:

01 Anchored Precision for Quality Assurance

Innovative pump head structure + nano-scale dispensing needles achieve ±1% accuracy in the 50–200 μL range (e.g., ±1 μL error for 100 μL doses).

02 High Consistency for Stable Long-Term Operation

Multi-roller positioning + spring-loaded tubing compression reduce pulsation. Internal data: <1% decay after 12 hours of continuous operation, outperforming traditional peristaltic pumps (>5% decay).

03 Efficiency Boost for Scalable Production

While maintaining precision, the WSP3000 achieves a filling speed of 120 bottles per minute and supports multi-device cascading, helping customers increase production line throughput.

04 Sterility and Contamination Prevention by Design

- Closed fluid path (only tubing contacts liquid) reduces cross-contamination risks.

- CIP/SIP compatibility with easy-disassembly tubing.

- Smooth surfaces with no sanitary dead zones, meeting GMP standards.

05 Smart Features for Simplified Operation

- Manual/automatic modes for easy production line integration.

- Intuitive UI with 3-tier user permissions for data security.

- UDP-based firmware/recipe updates via USB.

06 Gentle Handling

The gentle conveying method is suitable for complex liquid medicines such as suspensions and biologics, avoiding shear force damage to active ingredients and helping maintain drug stability.

In the field of inhalation and nasal drug delivery—an area with high technical barriers—cutting-edge treatment solutions rely on underlying precision manufacturing technologies for support. Lead Fluid, with its expertise in micro-fluidic precision control technology, has become a reliable partner for pharmaceutical companies in translating the concept of precise treatment into stable products.

Every precise spray carries the promise of health protection; behind each promise lies rigorous discipline across the entire chain from R&D to production. Lead Fluid will continue to deepen its expertise in the field of precision fluid handling, empowering more pharmaceutical research and advanced manufacturing with reliable, innovative, and verifiable solutions.

* Content Uniformity (CU) is a critical quality control indicator for pharmaceuticals, primarily used to evaluate the consistency between the actual content per unit and the labeled amount in low-dose or single-dose preparations.

* WSP3000 12-hour decay rate test: Under a production rate of 60 bottles per minute, filling data from 10 units were recorded every 12 hours. The system operated continuously for 5 days, with the maximum value taken as the result.