Some say: “More rollers mean a better pump.”

It sounds logical—more rollers should lead to smoother flow and higher precision, right?

But is this really true?

The answer is: Not necessarily.

Choosing the number of rollers is, in fact, an engineering trade-off involving smoothness, lifespan, and cost.

Gains and Losses of Increasing Rollers

Gains: Smoother Flow, Higher Precision

◎ Significant reduction in fluid pulsation

More rollers mean more compression cycles per rotation. The flow output becomes a superposition of more, smaller “peaks,” resulting in an overall smoother flow.

This is critical in applications highly sensitive to pulsation, such as chromatographic analysis or cell culture.

◎ Higher short-term flow accuracy

Reduced fluctuations lead to more stable instantaneous flow rates, making it suitable for experiments or detection systems requiring extreme short-term quantitative precision.

Losses: The Price of “Smoothness”

✕ Reduced tubing lifespan

Under the same speed and compression depth, more rollers often mean more compression cycles per unit time, accelerating tube aging.

✕ Increased operating heat

More rollers = more friction points = more heat generation. This not only speeds up tube degradation but may also cause performance deviations or instability when handling temperature-sensitive fluids.

✕ Higher complexity and cost

More rollers require a more complex pump head structure, more components, and larger size, typically leading to higher manufacturing costs and bulkier equipment.

*Note: The above analysis assumes identical basic pump head design and manufacturing quality, focusing solely on the impact of roller count. Actual performance is also influenced by factors like roller material, bearing precision, compression stroke, and tubing material.

Scenario-Based Selection: No “Best,” Only “Most Suitable”

Once we understand the “Gains and Losses”, the key question becomes: What matters most in your process?

Suitable for multi-roller pump heads (e.g., 4–8 rollers):

1 Core need: Flow stability

2 Typical scenarios: Precision analytical instruments (e.g., HPLC), cell perfusion

3 Reason: Even minor flow fluctuations can interfere with detection signals or reaction efficiency. In such applications, “smoothness” is the top priority.

Suitable for fewer-roller pump heads (e.g., 2–3 rollers):

1 Core need: Tube lifespan and cost-effectiveness

2 Typical scenarios: Industrial continuous filling, water treatment dosing

3 Reason: Slight pulsation usually doesn’t affect process outcomes, but frequent tubing replacement increases downtime and consumable costs. Here, “longer lifespan” is often the better solution.

Advanced Solutions: Balancing Smoothness and Durability

Can we achieve both “smoothness” and “durability“?

Lead Fluid’ s recommendations:

Solution 1: Multi-pump head with staggered phases

- Connect two (or more) independent pump heads in parallel, with their roller axes offset by a specific phase angle (e.g., 60°, 90°). The pulsations generated by each pump head compensate for each other at the outlet—when one head is at a peak, the other is at a trough—significantly reducing combined flow pulsation.

- Advantage:Achieves low pulsation similar to multi-roller pumps, while each pump head’ s tube experiences lower compression frequency, potentially extending overall tubing lifespan and reducing consumable costs.

(Note: The “lifespan advantage” here is relative to single multi-roller pump solutions. Phase staggering primarily reduces pulsation rather than directly extending tube life.)

Even better solution: Integrated design

DMD15 Pump Head

- Led Fluid’ s DMD series pump heads integrate the “multi-pump head parallel” principle into a single unit. Built-in roller phase compensation technologycancels out pulsations internally, delivering smooth flow.

- Advantage:No need to assemble multiple pump heads. Achieve low pulsation and high precision in one step.

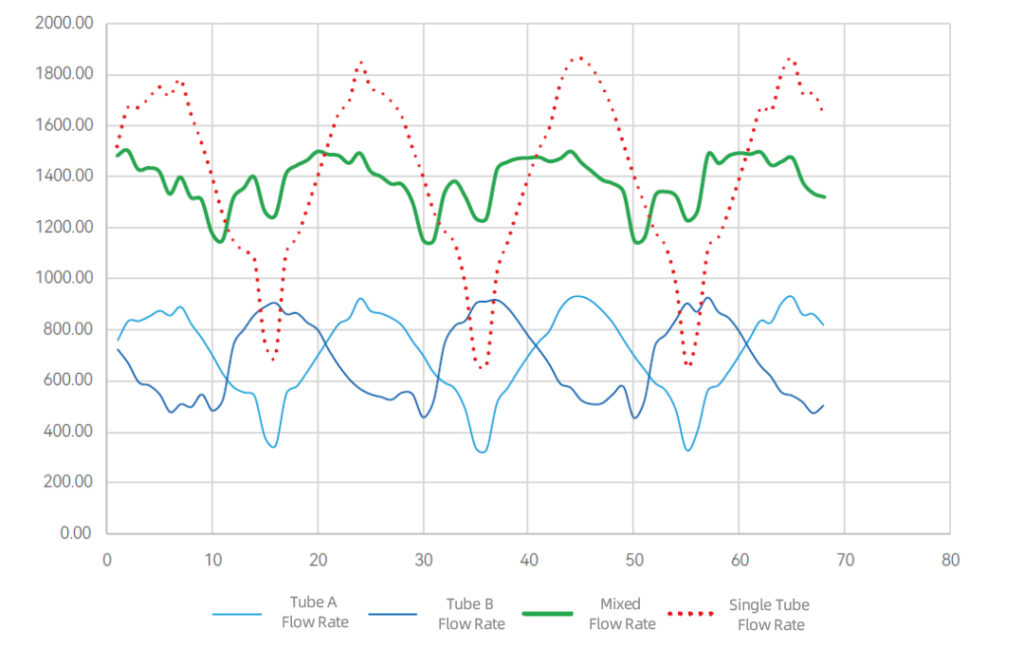

DMD15 Pulsation Curve Simulation Diagram

Note: DMD15 features A+B dual channels. The graph compares the combined flow pulsation (after mixing) with that of a single channel under the same flow rate and conditions.

Solution 2: Pulse dampeners

Lead Fluid ZN100 Pulse Dampener

- Installed at the pump outlet, it stores energy during flow peaks and releases it during troughs, “smoothing” the flow.

- Advantage:Simple structure, low cost, easy retrofitting. An economical way to improve system stability.

Note: While dampeners reduce pulsation, they introduce some volume retention and response delay. Evaluate carefully for systems sensitive to dead volume or instant response.

Conclusion: Are More Rollers Always Better?

Absolutely not.

The optimal choice depends on balancing flow smoothness, tube lifespan, operating cost, and system complexity for your specific application.

When selecting, ask yourself:

In my process, is smoothness more critical, or are minimizing downtime and lowering consumable costs more important?

The answer will guide your decision.

If you still face challenges in selection,

Lead Fluid’ s technical team offers 1-on-1 professional support—considering your fluid properties, flow range, and budget—to help you find an efficient, reliable, and economical solution.