Real‑World Conditions Are Tough—and Unforgiving

Frequent cleaning and sterilization, hot and humid splashing, confined spaces, airborne dust, and corrosive aerosols…

In such environments, equipment must deliver not only precision, but also stability, durability, and compactness.

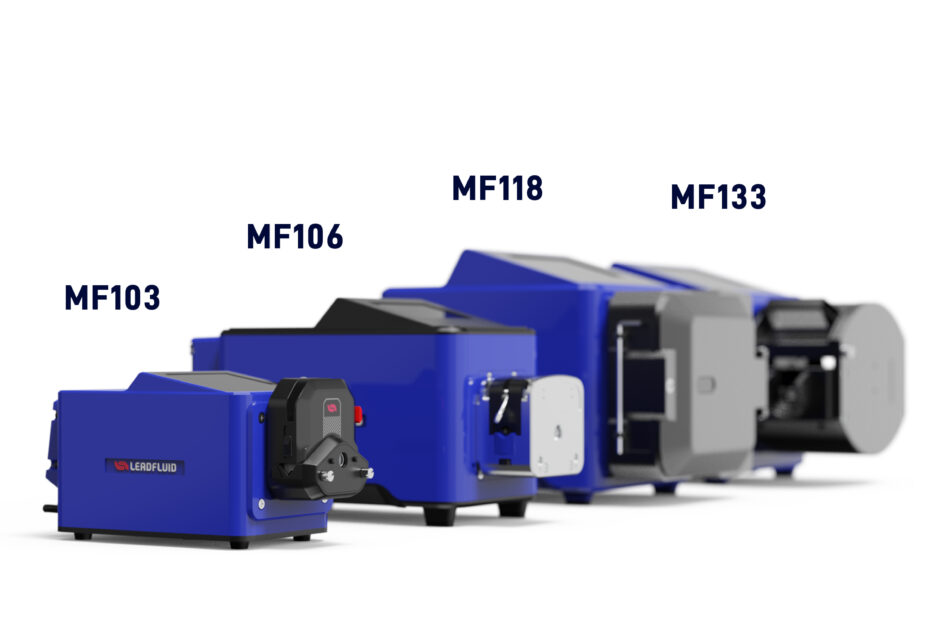

The Lead Fluid MF103 High‑Protection Peristaltic Pump was engineered exactly for these challenges.

With a compact near‑point installation, precise flow control up to ≤ 3000 mL/min, and an IP66 protection rating, MF103 brings the concept of “small yet stable” into real‑world operation.

Designed for a wide range of applications, including biopharmaceuticals, laboratories, new energy, textile printing & dyeing, marine science, and coating processes.

✨ Key Highlights

1️⃣ Small Yet Precise: Premium Materials • Precision Engineering

🔸 Integrated closed‑loop stepper motor

High torque output ensures excellent stability, accuracy, and repeatability.

🔸 One‑piece die‑cast aluminum housing with anti‑corrosion coating

Robust structure, corrosion‑resistant, and easy to clean.

🔸 IP66 dust‑ and water‑proof protection

Ideal for dusty environments, biopharmaceutical cleanrooms, and wash‑down applications.

2️⃣ Small Yet Space‑Saving: Compact Design • Efficient Layout

🔸 Near‑process installation

Compact form factor allows placement close to the process point, minimizing response delay.

🔸 High‑density layout friendly

Reduces installation complexity, retrofitting work, and benchtop occupation.

3️⃣ Small Yet User‑Friendly: Flexible Deployment • Easy Operation

🔸 Lightweight and compact

Supports quick redeployment between workstations or temporary capacity expansion—ideal for R&D, pilot, and small‑scale production.

🔸 4.3‑inch full‑color touchscreen with new UI

Clean interface, intuitive operation, fast learning curve.

🔸 Five operating modes

Flow rate, dispensing (volume), time dispensing, programming, and external control—covering diverse process requirements.

🎯 Typical Application Scenarios

🧪 Biopharmaceuticals (R&D & Production)

Buffer and media preparation, fermentation, purification processes including clarification, concentration, ultrafiltration, diafiltration, and chromatography.

🔬 Laboratories

Perfect for applications with limited benchtop space and frequent cleaning demands.

🏭 Industrial Environments (Printing, Dyeing, Coating, etc.)

Reliable operation in humid, dusty, or corrosive aerosol environments, balancing high protection with easy maintenance to reduce failures and downtime.