If a 1kg steel ball drops from a height of 40cm, will the glass screen shatter?

At Lead Fluid, this is not a hypothetical question—it’s a real-world test.

Why conduct such tests?

Lead Fluid consistently adheres to the principle of “letting experiments and data speak.” Every pump manufactured by Lead Fluid must pass rigorous factory inspections before delivery, ensuring uncompromised quality control from production to deployment.

This is especially critical in high-risk sectors such as chemical plants, mining, and petroleum extraction, where reliable and compliant products form the foundation of safety. True reliability is determined by a device’s ability to perform stably under complex working conditions—not just by theoretical specifications.

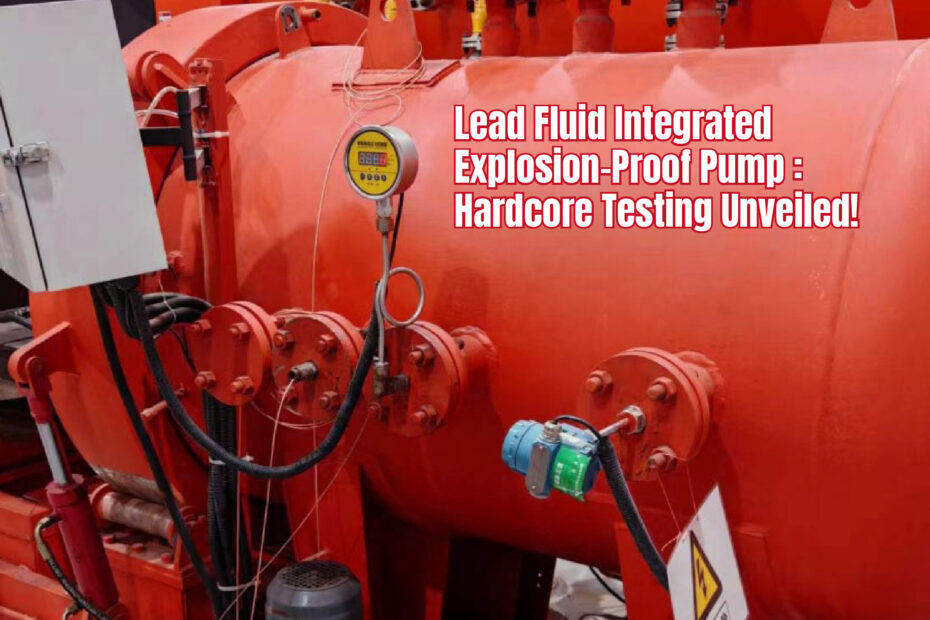

Today, we put the Lead Fluid Integrated Explosion-Proof Pump through a series of hardcore tests to reveal its safety credentials:

01 Impact Test

As a key component of the explosion-proof enclosure, the mechanical strength of the screen glass directly affects overall safety.

Test Procedure

1 Select a sample of the explosion-proof pump’s screen glass.

2 Use a 1kg impactor, released vertically from a height of 40cm, to strike the glass surface.

Acceptance Criteria

No cracking, shattering, or structural damage to the glass.

Test Result

The glass remained intact with no signs of cracking or breakage.

This outcome stems from our strict material selection process—Leifu evaluated multiple tempered glass suppliers and selected the highest-performing option, which passed both high-temperature (≥90°C) and impact resistance (≥4J) tests.

02 Overpressure Test

The safety principle of explosion-proof equipment is that the enclosure must withstand internal explosion pressure without rupturing or leaking.

Test Procedure

1 Fill the complete enclosure with water to form a sealed cavity.

2 Gradually increase pressure to 2.0MPa (approximately 20 times atmospheric pressure) and maintain for 10 seconds, monitoring for deformation or leakage.

Acceptance Criteria

No permanent deformation of the enclosure; no leakage at any explosion-proof joint.

Test Result

At 2.0MPa, the enclosure showed no structural deformation or leakage.

This performance is attributed to the pump’s cast-aluminum integrated housing, combined with rational structural design, precision machining, and multi-layer sealing technology.

03 Explosion-Proof Certification

To serve global markets, we submitted the Leifu Integrated Explosion-Proof Pump to the TÜV Rheinland laboratory.

TÜV Rheinland is a notified body under the EU ATEX Directive and a certification body under IECEx (International Electrotechnical Commission System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres). Their certification process is renowned for its stringent testing and transparency.

Among all tests, “internal ignition non-transmission” is one of the core indicators validating explosion-proof performance. It verifies whether the equipment can prevent flames or explosive effects from spreading to the external environment when ignition occurs internally.

Test Setup

Inside the equipment, highly explosive media such as hydrogen and acetylene were ignited to simulate extreme internal explosion scenarios.

Test Result

Ignition did not transmit externally! The surrounding environment remained safe, and the structural and sealing systems stayed intact.

Safety is not a corporate monologue—it’s a consensus with our customers. We welcome you to visit the Lead Fluid laboratory, witness the testing process firsthand, and understand the significance behind each data point. Moving forward, Lead Fluid will continue to adhere to standards and act with responsibility, delivering trusted explosion-proof solutions for users worldwide.