In the fields of air quality monitoring and environmental safety, formaldehyde is a “high-profile player.” As a common indoor pollutant originating from new furniture, plywood, wall paint, etc., long-term exposure to high concentrations of formaldehyde can adversely affect human health. Consequently, there is a growing need across various scenarios—from laboratories to field applications, and from research institutions to environmental protection agencies—for real-time and accurate monitoring of formaldehyde concentrations in the air.

01 Precise Fluid Control Ensures Data Reliability

Currently, online formaldehyde analyzers widely adopt the Hantzsch (acetylacetone) reaction method. This method involves absorbing formaldehyde from gas samples into an absorption solution, where it reacts with acetylacetone reagent to form a fluorescent compound. Concentration is then determined via fluorescence detection. This process is highly sensitive to reagent ratios, reaction time, and mixing uniformity:

Excessive flow fluctuations → Imbalance in reactant ratios, leading to measurement deviations.

Unstable fluid delivery or bubbles → Discontinuous detection signals or even errors.

Insufficient tubing lifespan → Compromises long-term online monitoring capabilities of the instrument.

02 Requirements of Peristaltic Pumps in Formaldehyde Online Analyzers

In high-sensitivity formaldehyde monitoring, peristaltic pumps are responsible for reagent delivery and serve as critical components for achieving automation, precision, and stability. Core customer requirements include:

Low Flow Rate & High Stability

Typical requirement: 0–5 mL/min with minimal fluctuation.

Continuous Reliability

Stable long-term output with low maintenance frequency.

Chemical Compatibility

Corrosion-resistant tubing without leaching impurities that could affect detection.

Ease of Integration & Communication

Compatibility with main control systems for convenient machine configuration.

03 Lead Fluid Provides a Stable “Heart” for High-Sensitivity Monitoring

To address these requirements, Lead Fluid offers an integrated solution comprising:

High-performance stepper motor drive + DS6-4 pump head + Pharmed long-life tubing + RS485 communication.

• Precise Low-Flow Control

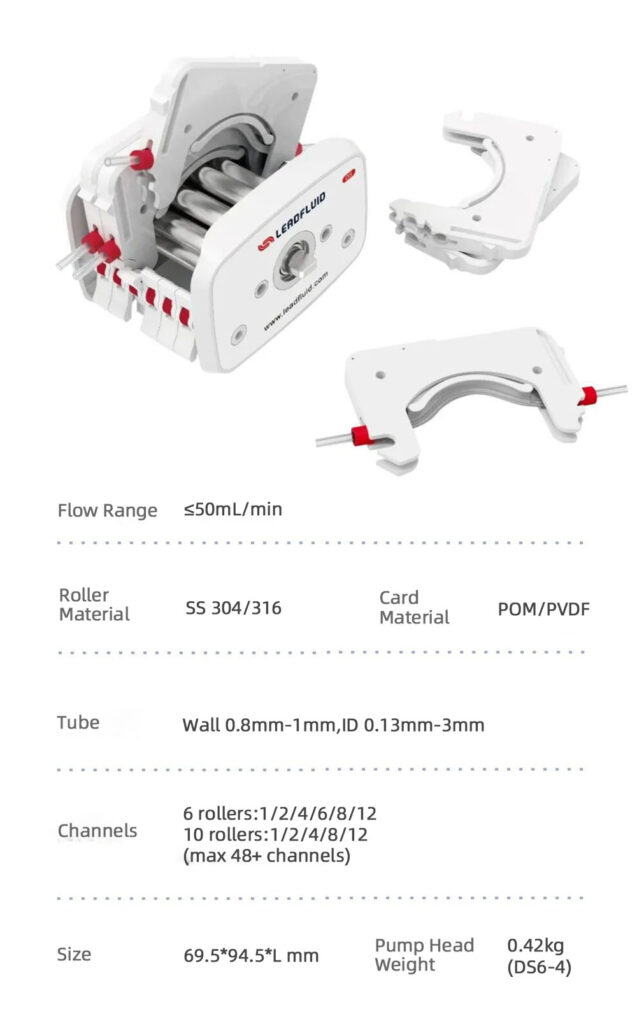

The DS series pump head combines multi-roller design (6/10 rollers) with high-precision stepper motor control to effectively reduce pulsation, covering a broad flow range of 0–50 mL/min (suitable for 0–5 mL/min applications).

It supports synchronous transfer across 1–48+ channels, with precision mechanical structures and high-standard machining ensuring multi-channel flow consistency and repeatability.

• Durable Materials & Chemical Compatibility

The pump head features PVDF/POM cartridges and high-strength stainless steel rollers, paired with chemically resistant tube such as Pharmed®, enabling long-term resistance to formaldehyde absorption solutions, Hantzsch reagents, and other common media. This reduces leakage risks and decreases maintenance frequency.

• Stable Continuous Operation

The tube compression device supports adjustable settings or spring self-adaptation, compatible with tube of different wall thicknesses and transmission pressures, extending tubing service life.

Cartridge-style loading/unloading structure allows quick tubing replacement, minimizing downtime.

The separate design of the pump head and drive unit enhances heat dissipation, further ensuring operational stability.

• High Integration & Intelligent Control

Compact design for easy integration into various analyzers.

RS485 communication enables real-time interaction with the main control system, allowing automated start/stop and flow switching based on cycles.

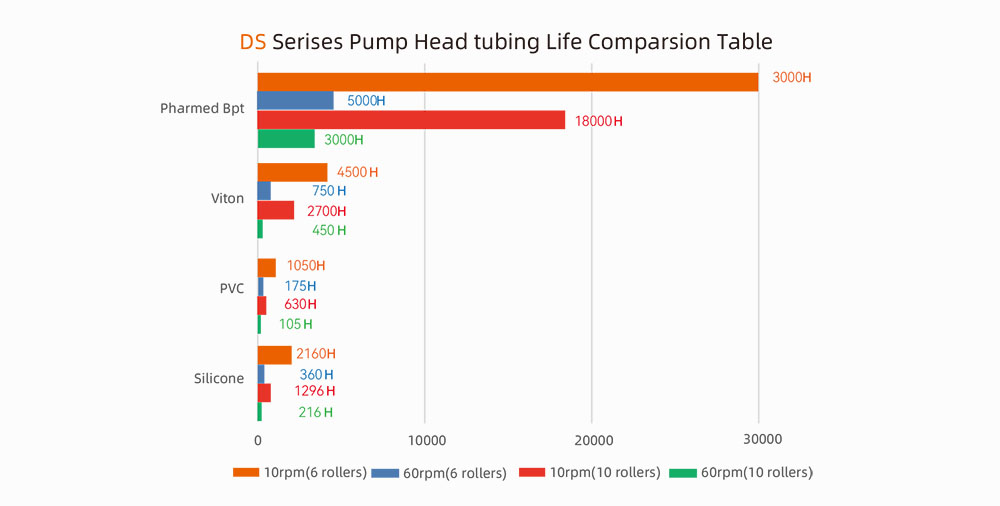

04 DS Series Tube Lifespan Reference Table

Notes:

The above data are all test results obtained by Lead Fluid laboratory under normal temperature and pressure for the transmission of pure water, which are for reference only; the actual service life may be affected by specific factors such as pressure, temperature, medium characteristics, tube batch and wall thickness; for specific problems, please contact Lead Fluid engineers to get better technical support.

As environmental standards become increasingly stringent, formaldehyde monitoring has expanded from laboratories to various field and online monitoring projects. Lead Fluid peristaltic pumps serve as stable and reliable fluid delivery units in such applications, ensuring low-flow, long-cycle, and high-consistency fluid control. They provide solid technical support for urban air quality monitoring and indoor environment assessment.