In the previous article, we gained an initial understanding of the MF103 High‑Protection Peristaltic Pump.

Today, let’s take a closer look inside this compact unit to uncover the core design features and technical details that make it powerful.

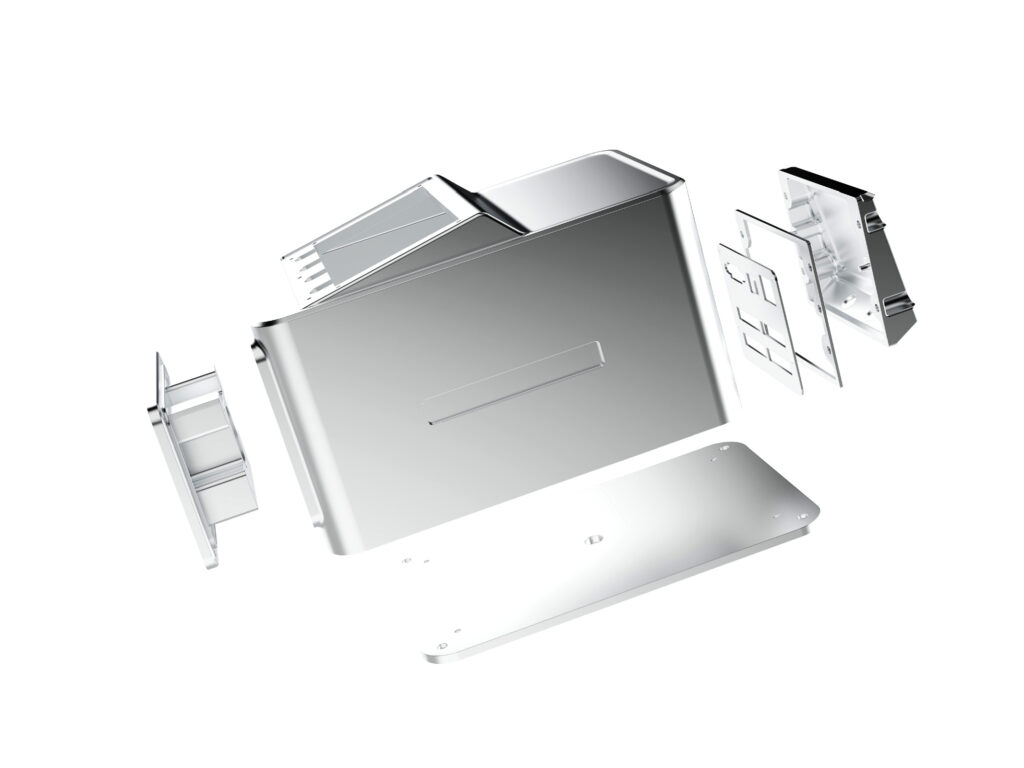

01“Armor Body”

Die‑Cast Aluminum × Anti‑Corrosive Coating

(Die‑cast aluminum integrated housing)

(Anti‑corrosive surface coating)

A solid foundation for long‑term stable operation.

A solid foundation for long‑term stable operation.

MF103 adopts an integrated die‑cast aluminum housing with high structural strength and resistance to deformation, resulting in a more compact body.

Its exterior is treated with anti‑corrosive powder coating, designed to withstand chemical splashes in laboratories and corrosive media in industrial environments. The surface is easy to clean and maintain, ensuring durability and stability under humid, dusty, or high‑frequency disinfection conditions.

02“Smart Window”

4.3‑inch Color Touch Screen

Intuitive interaction, efficient control at your fingertips.

The 4.3‑inch color touchscreen combines with a simplified operation interface, making key parameters clear at a glance.|

Settings can be completed directly via touch, reducing learning effort and enabling precise, rapid control even under busy working conditions.

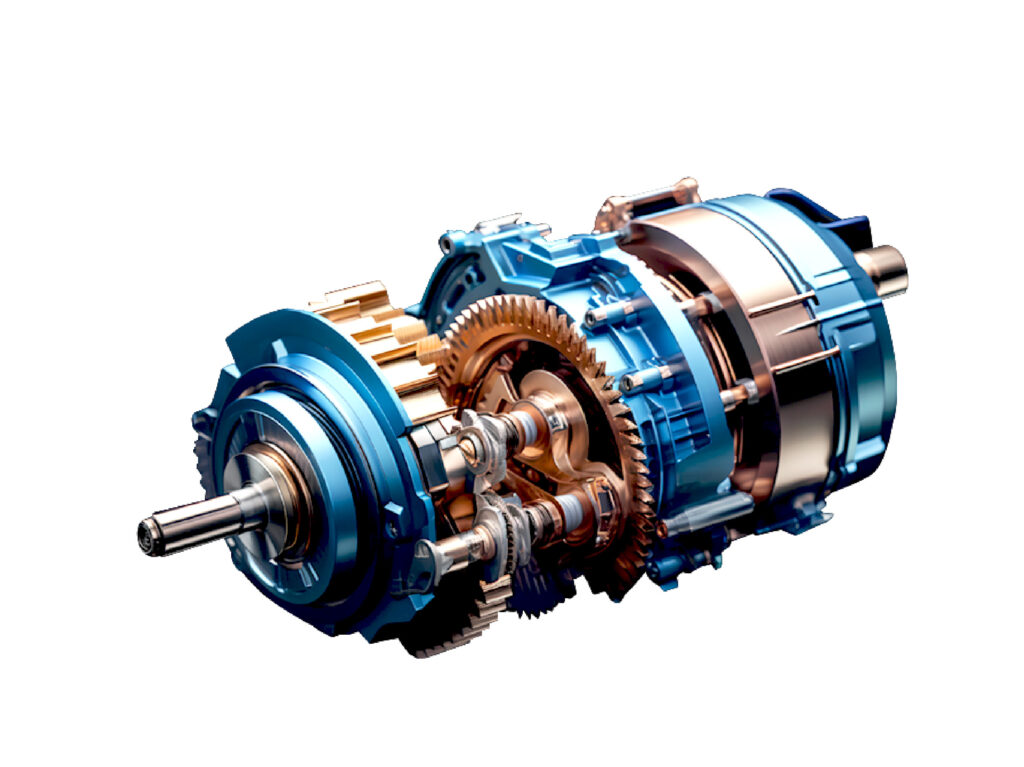

03 “Power Core”

Servo Motor

Supporting precise control.

Driven by a servo motor, MF103 provides strong load resistance, high control accuracy, and excellent low‑noise performance.

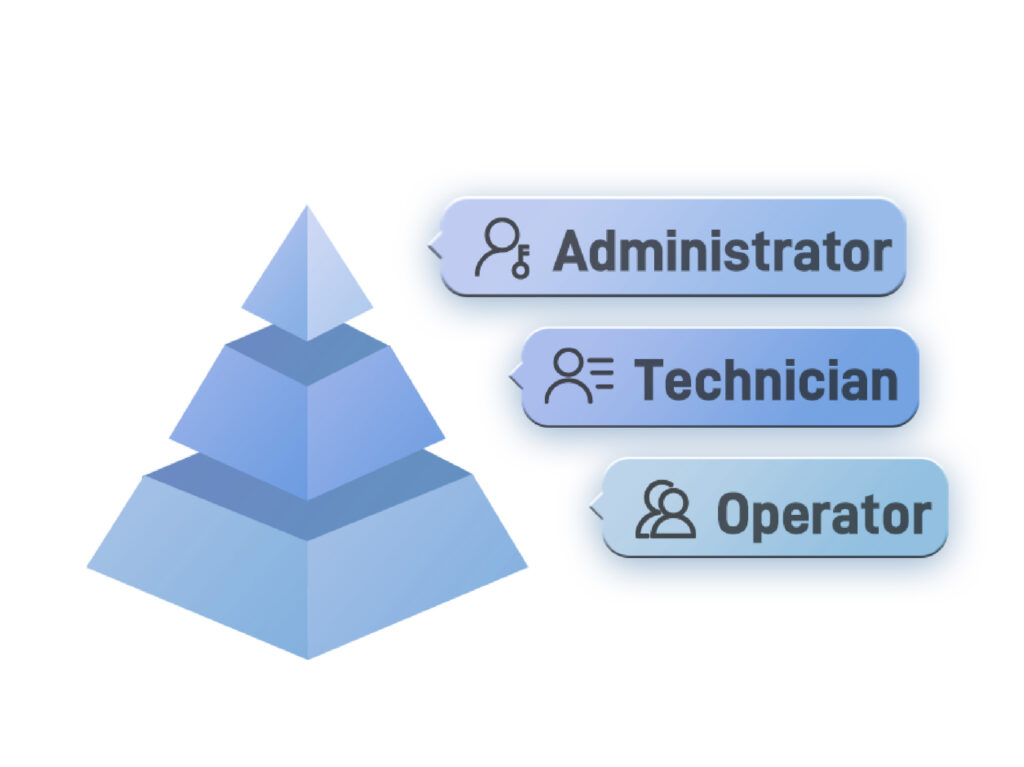

04“Key to Management”

Three‑Level User Permission

Hierarchical authorization, standardized and controllable.

For highly regulated applications such as biopharmaceutical or fine chemical processes, MF103 offers three‑level user management.

Access and modification rights are divided according to user roles, preventing unintended parameter changes and enabling compliant operation management.

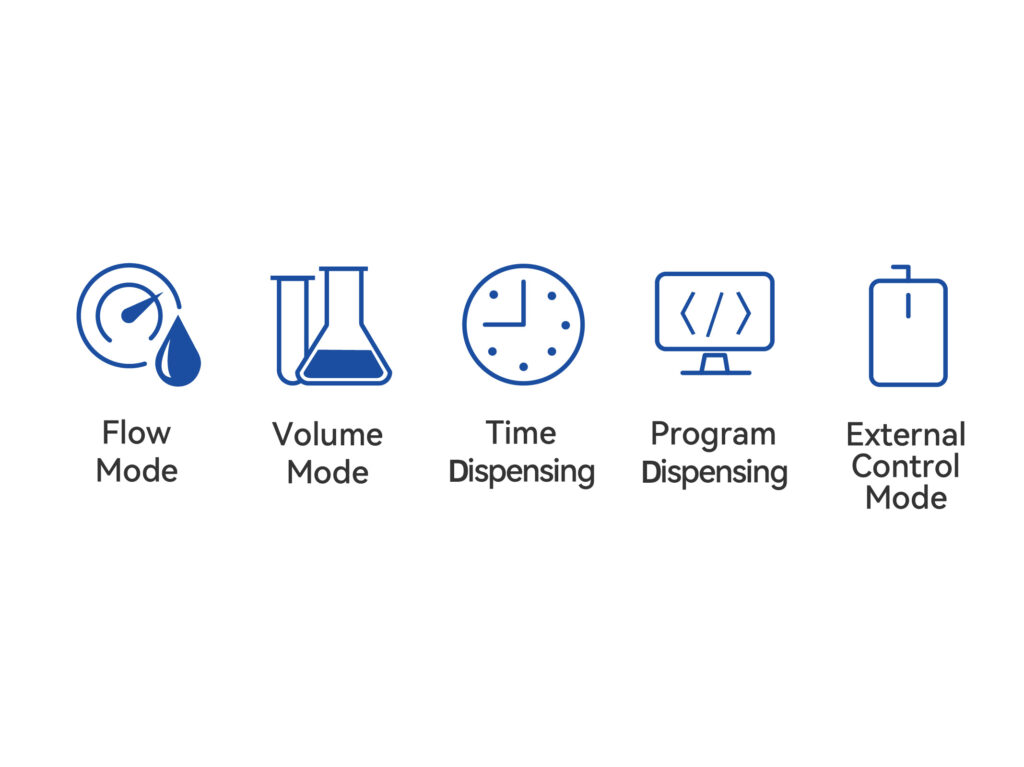

05“Wings of Modes”

Five Operating Modes

One unit, multiple functions — adaptive to different process rhythms.

- Flow Mode: Continuous and stable liquid delivery or dosing, suited for continuous processes.

- Volume Dispensing Mode: Dispenses preset liquid volumes with improved accuracy.

- Time Dispensing Mode: Transfers fluid at timed intervals, convenient for beat‑based control.

- Program Mode: Supports up to 30 programmable steps; cycles and intervals can be set to minimize manual intervention.

- External Control Mode: Accepts various external signals for integration with host computers or PLCs.

Technical Value Empowerment

Ultimately, every design element of the MF103 targets essential on‑site needs: environmental resistance, ease of operation, high precision, and flexibility.

This is not a mere combination of parameters, but the embodiment of Lead Fluid’s deep understanding and engineering practice of reliable fluid transfer.