Driving Motors

The rapid development of new energy vehicles has placed the performance and reliability of drive motors under the spotlight. As the “heart” of new energy vehicles, motors must operate stably under high voltage, high speed, and complex working conditions. Insulation treatment is a critical process ensuring their safety and durability.

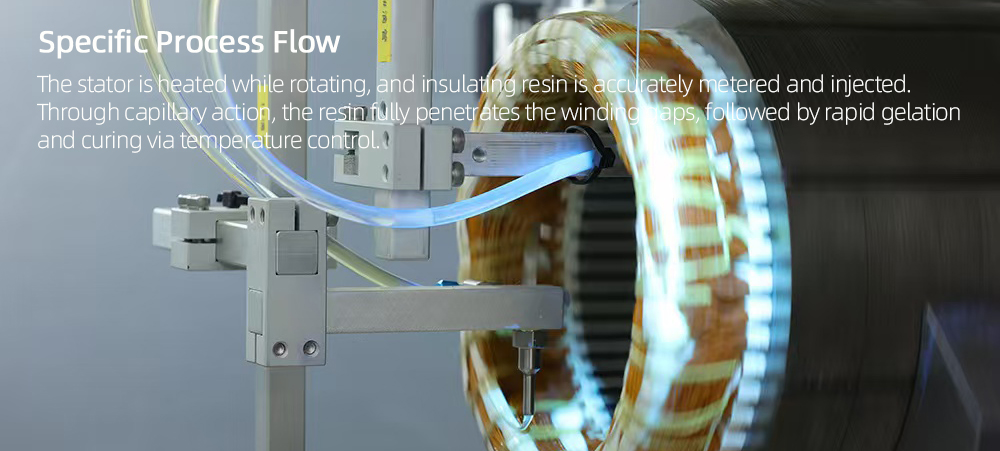

Among various insulation processes, electric heating drip impregnation technology has become a core step in the manufacturing of flat wire motors. This process involves rotating and heating the stator to precisely and uniformly permeate insulating resin into the windings, forming a dense and complete insulation layer that significantly enhances motor reliability and performance.

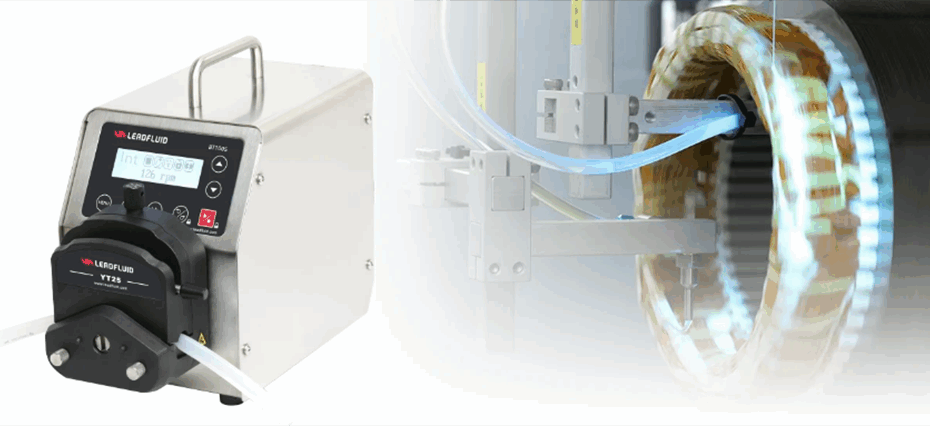

The stable implementation of this process relies on reliable fluid transfer equipment. The Lead Fluid BT100S peristaltic pump is the customer’s preferred solution for addressing this challenge.

What Is Drip Impregnation?

If motor windings are compared to a small wooden house, drip impregnation is like painting protective varnish on the house:

• Moisture Protection: Enhances motor reliability in high-temperature, high-humidity environments.

• Reinforcement: Improves mechanical strength of coils, reducing vibration-induced loosening.

• Longevity: Uniform and dense insulation significantly extends motor service life.

• Safety: Reduces risks of partial discharge and short circuits.

However, drip impregnation is far more complex than painting—it is a rigorous and precise process.

Process Challenges

The main challenges in electric heating drip impregnation lie in resin delivery:

01 Stability: Flow fluctuations cause uneven insulation thickness and degraded performance.

02 Precision: Excessive flow leads to resin overflow, contaminating the iron core and increasing cleanup efforts.

03 Specificity: Resin often requires heating to maintain fluidity, demanding higher performance from pumps and tube.

04 Flexibility: Different stages require dynamic adjustment of drip speed, necessitating rapid response and precise control.

Previously, the customer tried diaphragm pumps, but significant pulsation made smooth flow control difficult, resulting in uneven impregnation that failed to meet the stringent requirements of high-end manufacturing.

Lead Fluid Solution

After multiple rounds of testing and comparison, the customer ultimately adopted the Lead Fluid peristaltic pump solution:

Configuration

BT100S Drive + YT25 Pump Head + A-60-F Tube

Operating Conditions

The resin is heated to a suitable temperature to maintain fluidity, with the BT100S ensuring continuous and precise transfer.

01 Precision and Stability for Uniform Coating

The BT100S features a high-performance stepper motor with a speed control accuracy of ±0.2%, ensuring precise and stable flow. This guarantees uniform and dense insulation coating, fundamentally reducing resin overflow caused by flow fluctuations or overload, thereby minimizing iron core contamination and material waste while improving product consistency and yield.

02 Anti-Drip Design to Prevent Contamination and Waste

The slow-stop and back-suction functions prevent resin dripping during shutdown, maintaining equipment cleanliness and reducing unnecessary cleaning steps.

03 Strong Anti-Interference for Complex Power Environments

Supports wide voltage input with superior anti-interference characteristics, ensuring stable operation in industrial environments with multi-device and high-power interference, guaranteeing production continuity.

04 Automation Integration

RS485 communication, compatible with Modbus protocol, enables integration with PLCs and other upper-level systems to meet industrial automation needs.

05 Reliability and Ease of Maintenance

Pump body made of stainless steel for corrosion resistance and easy cleaning.

YT25 pump head features a robust structure with stainless steel rollers, suitable for high-speed and long-term operation.

A-60-F tubing is heat-resistant, corrosion-resistant, and abrasion-resistant, significantly extending service life and reducing maintenance costs.

06 User-Friendly Operation

Tube is the only consumable; replacement requires no tools and takes just minutes.

Equipped with LF-LCD-OS software system for intuitive operation, reducing training barriers.

Lead Fluid understands that the stability of every component in industrial applications determines the success of the entire production system. We provide not just a pump, but a trustworthy fluid transfer solution.

If you are planning or upgrading a drip impregnation production line, or seeking a clean, controllable, and efficient fluid transfer solution, please contact us. The Lead Fluid team will provide professional technical support and solutions to help you achieve process upgrades and more reliable manufacturing quality.