Introduction

• Innovative Technology with Automatic Tube Return

Effectively prevents abnormal wear on hoses, extends service life, and reduces maintenance frequency.

• Low Pulsation Delivery Technology

Utilizes patented micro-pulsation technology (Patent No. 201420691450.5) to achieve precise and stable low-pulsation delivery, ensuring high reliability for critical applications.

• Compact Size with High Flow Rates

Compact design with a maximum flow of 607.7 mL/min, increasing flow rates by 50% compared to similar-sized products, meeting diverse needs.

• Convenient Twist Cap Design

Ergonomically designed twist cap for easy opening and simplified operation.

• Personalized Color Options

The KX1502 features a standard sky blue color with support for multicolor customization to meet your personalized needs.

• Visible Operation

Transparent housing allows for clear visibility of the internal operating status, facilitating real-time monitoring and maintenance.

• Flexible Compatibility

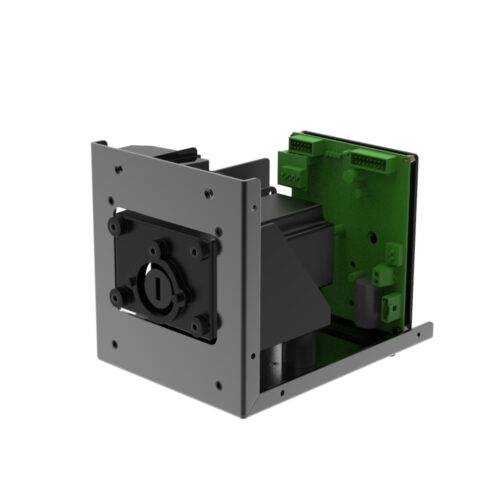

Multiple installation options enhance flexibility in various application scenarios.

• Cost-effective

Balances high performance with economical pricing, providing competitive fluid transfer solutions.

Pump Parameters

Channels: 1

Rollers: 2

Speed Range: 1~300rpm

Flow Range: 0.16~607.7mL/min

Tube Fixation Method: Tube Joint Fixation

Tube Compression Gap: Fixed Gap

Shell Material: PA6 White

Roller Material: PVDF Material

Motor: 42 Stepper motor

Power Voltage: DC 24V

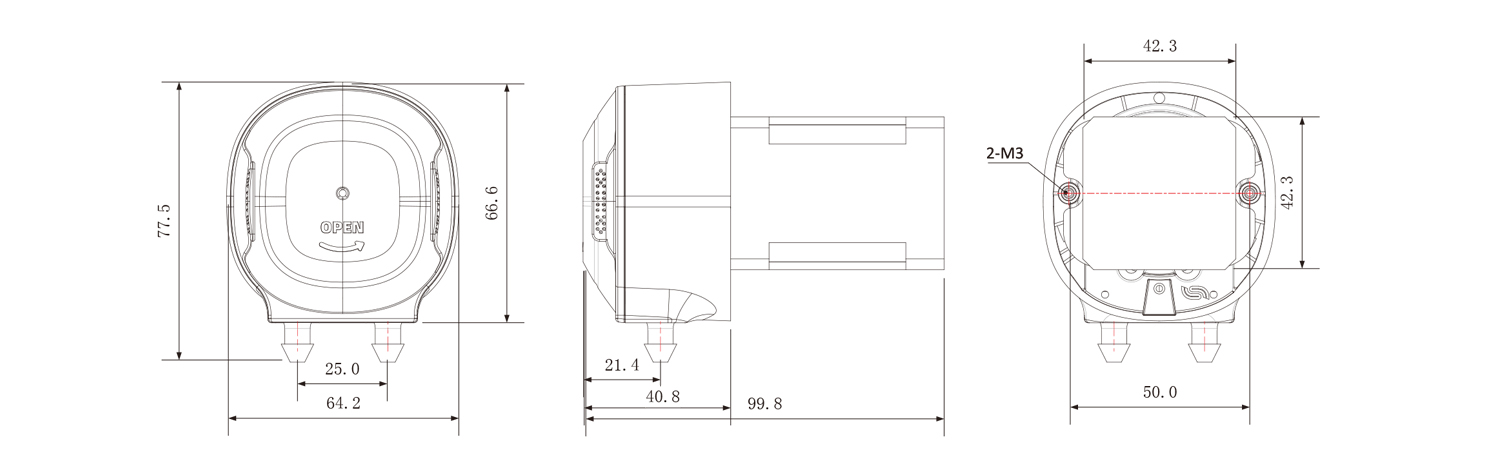

Dimensions (L×W×H): 99.8×64.2×77.5mm

Working Environment: Temperature: 0-40℃, Humidity: <80% RH

Weight: 591.5g

Applicable Tube Model and Flow Reference Table

| Tubing Material | Speed(rpm) | 14# | 19# | 16# | 25# | 17# |

| Silicone | 1 | 0.16 | 0.33 | 0.56 | 1.25 | 2.02 |

| 10 | 1.65 | 3.37 | 5.62 | 12.5 | 20.3 | |

| 50 | 8.25 | 16.8 | 28.1 | 62.5 | 101.5 | |

| 100 | 16.7 | 33.7 | 56.3 | 125.3 | 203.5 | |

| 200 | 33.3 | 67.5 | 112.3 | 250.3 | 405.7 | |

| 300 | 49.5 | 101.1 | 167.7 | 375.3 | 607.7 |

| Tubing Material | Speed(rpm) | 19# | 16# | 25# |

| Pharmed | 1 | 0.36 | 0.53 | 1.18 |

| 10 | 3.63 | 5.33 | 11.9 | |

| 50 | 18.1 | 26.6 | 59.5 | |

| 100 | 36.3 | 53.3 | 119.3 | |

| 200 | 72.6 | 106.5 | 238 | |

| 300 | 108.7 | 157.7 | 355.7 |

The above flow data were all tested using a Lead Fluid silicone tube to pump pure water under laboratory conditions with normal temperature and pressure. This data is for reference only. Due to pressure in actual use , temperature, medium characteristics, tube material and other specific factors,the specific situation needs to consult our engineers.

Motor Panel Mounting Hole Diagram

Unit: mm

Application Fields:

Industrial, environmental, food and beverage, laboratory, medical, etc.

Typical Applications:

Disinfectant machines, beverage dispensers, milk tea machines, blood analyzers, water quality analyzers, etc.

Statement: The final explanation right of above information belongs to Lead Fluid.