Feature

•Compact Design

Compact cast‑aluminum body with powder‑coated finish — lighter and more space‑saving, while offering excellent heat dissipation and corrosion resistance.

• IP66 High Protection Rating

Effectively resists dust, water jets, humidity, and mild acid‑alkali salt spray, ensuring long‑term stable operation.

•Five Operating Modes for Multi‑Scenario Adaptability

Five operating modes—flow rate, volume, time dispensing, programming, and external control—flexibly adapt to diverse working conditions and application requirements.

•Simple and User‑Friendly Operation Experience

Building on the unified interface layout and control logic of the series, it enables quick familiarization and offers intuitive, convenient operation.

•High‑Speed, High‑Torque Drive

Driven by an integrated closed‑loop stepper motor, delivering up to 600rpm and 0.8N·m torque, it offers precise feedback and stall‑alarm protection to ensure stable and reliable fluid transfer.

•4.3‑Inch Color Touchscreen

Provides more comprehensive information display with clear, intuitive parameter status, enhancing the visualization and overall user experience.

•Smart Connectivity and Collaborative Operation

Supports RS232 and RS485 communication and is compatible with the Modbus protocol, enabling seamless integration into various automation systems.

•Three‑Level User Access Management

Prevents accidental operations and unauthorized parameter changes, meeting management requirements for compliance‑critical applications

Technical Parameter

Flow Range: 0.00023-3000mL/min

Speed Range: 0.1-600rpm

Speed Resolution: 0.1rpm

Speed Accuracy: <±0.2%

Delayed Start Time: 1 second–999 hours

Timed Running Duration: 1 second–999 hours

The Time of Dispensing: 0.1 second -99.9 second

Loop Count: 1–9999 cycles, 0 for infinite loop

Interval Time: 0.1- 999 seconds/minutes/hours

Reverse Angle: 0-720 degrees

Working Mode: Flow mode, volume dispensing mode, time dispensing mode, programming mode, and external control mode

Adjustment Method: Touch screen operation

Display Mode: 4.3‑inch IPS color LCD

External Control Signals: Selectable 5V/12V/24V level inputs; optional speed control via 0–5V, 0–10V, or 4–20mA signals. Supports start/stop and direction control with electrical isolation, and provides output signals for start/stop and direction.

External Digital Communication: RS485, RS232, and Ethernet interfaces supporting the Modbus communication protocol.

Power Supply Voltage: AC 100-240V 50Hz-60Hz

Power: <65W

Protection Degree: IP66

Working Environment: Operating temperature: 0–40°C, operating humidity: <80%

Shell Material: Aluminum

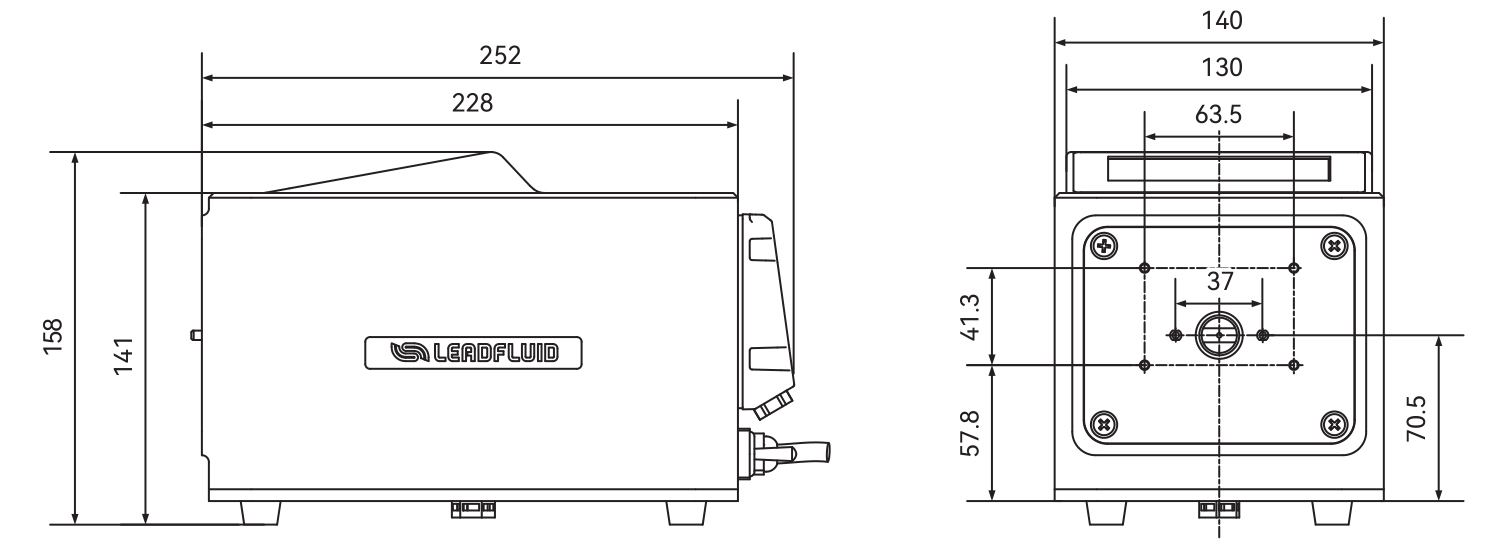

Dimensions(L×W×H): 252x140x158mm

Driver Weight: 5.15kg

MF106 Applicable Pump Head and Tube,Speed, Flow

| Drive Type | Pump Head | Channel | Tube | Single Channel Flow Rate (mL/min) |

| MF103 | DS6/10 | 1,2,4 | Wall 0.8-1mm,ID≤3.17mm | 0.0006-48 |

| DT10-18 | 1 | 13# 14# Wall 0.8-1mm, ID≤3.17mm | 0.00023-64 | |

| DT15-24 | 2 | 19# 16# 25# 17# | 0.067-2200 | |

| DMD15 | 1 | 13# 14# 19# 16# 25# | 0.01-2070 | |

| YZ15/YZ15T | 1 | 13# 14# 19# 16# 25# 17# 18# | 0.005-2500 | |

| YT25 | 1 | 15# 24# 35# 36# | 0.18-3000 |

Above flow parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure, in actually using it is effected by specific factors such as pressure, medium etc. Above for reference only.

Dimension(mm)

Application fields:

Biopharmaceuticals, Mining, Petrochemical, Food Industry, and More

Typical applications:

Raw Liquid Transfer, Mining Flotation Reagent Addition, etc.