Functions and Features

• The golden ratio design combined with a sleek blue shell presents a streamlined, technological aesthetic. The ergonomic design ensures comfortable and effective operation.

• The 5-inch LCD screen offers a wide viewing angle, providing clear visibility from any perspective.

• Setting parameters is simple, and displacement adjustments are more efficient.

• With Lead Fluid’s patented calibration algorithm, it conserves three times the original liquid and boosts efficiency by threefold.

• The three-level permission management system is particularly suitable for pharmaceutical factories and other industrial environments.

• No rewiring needed, easily switch between different analog types.

• Offers multiple communication modes, including network communication.

• With 400w power, it can cascade up to 10 pump heads (yz15t silicone tube)

• Designed for wide voltage ranges, suitable for 100-240V.

Specifications

Explosion proof standard:GB/T 3836.1-2021 GB/T 3836.2-2021 GB/T 3836.31-2021

Flow range: 0.006-33000mL/min

Speed range:0.1-600rpm

Speed resolution: 0.1 rpm

Speed accuracy: <±0.2%

Display: 5 inch industrial grade color LCD screen

Operation:Explosion proof button with 8 keys

Working mode: Flow mode, volume dispensing mode, time dispensing mode, external control mode, programming mode

Delay start time: 1S-999H

Scheduled working time: 1S-999H

Working time: 0.01-99.99S/M/H

Dispensing volume: 0.001-9999L

Dispensing time: 0-999, 0 means circle

Dispensing interval time: 0.1-999S/M/H

Suction angle: 0-720°

External control signal input: (1) Start/Stop: External control input level (5~24V); (2) Forward/Reverse: External control input level (5~24V); (3) Speed Regulation: Analog 0~5V, 0~10V, 4~20mA can be set.

External control signal output: (1) Start/Stop: Level Signal (following input voltage); (2) Forward/Reverse: Level Signal (following input voltage); (3)Analogue output 0~5V

Communication interface:RS485, RS232, Ethernet support Modbus protocol, Profibus extension (optional)

Power supply: AC 100-240V 50Hz-60Hz

Working environment: Temperature 0 ~ 40℃, relative humidity<80%

Shell material: Aluminium alloy

Power consumption: <400w

IP grade: IP66

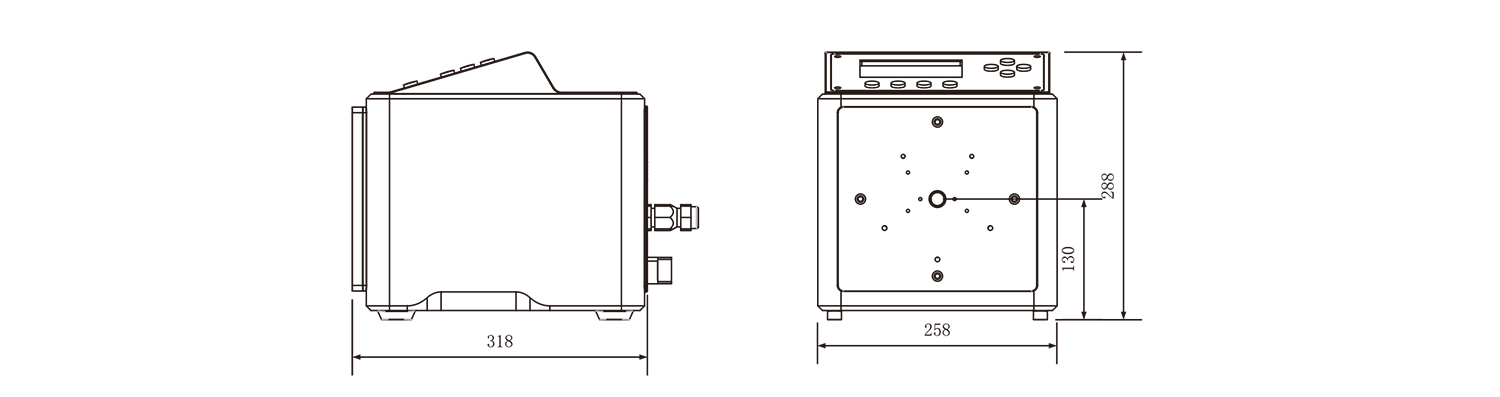

Driver dimension(L×W×H): 318mm×258mm×288mm

Weight: 28kg

Flexible Tube Model And Flow Parameters

| Pump Drive | Pump Head | Channels | Max Speed(rpm) | Tube Material | Tube Model | Max Flow(mL/min) |

| AF9a-b | YT15-E | 1 | 600 | All series | 13#14#19#16#25#17#18# | 0.006-2700 |

| YT25-E | 1 | 600 | All series | 15#24#35#36# | 0.17-3000 | |

| YZ35-E | 1 | 360 | All series | 73#82# | 1.3-13000 | |

| KL40 | 1 | 600 | All series | 186#187# | 7.8-20000 | |

| PL48-E | 1 | 600 | All series | 193#88#191#92# | 2.2-33000 |

Above flow parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure, in actually using it is effected by specific factors such as pressure, medium etc. Above for reference only.

Dimension(mm)

Applications

Application fields: Biopharmaceuticals, Petrochemical, Mining, Printing and Dyeing Industry, Food Industry,and More

Typical applications: Coating and Granulation, Flammable Liquid Filling, Chemical Synthesis Reactions,Petroleum Refining, etc.