Features

■Industry-First OLED Display. Real-time display eliminates blind operation.

The first-generation LED status light (Patent No.: ZL 201621348864.3) has been upgraded to an OLED display, dynamically showing the syringe piston position and valve status for more intuitive operational feedback.

■CAN Bus Protocol. Meets the needs for efficient control

The addition of the CAN bus protocol provides high-speed, stable, and interference resistant communication capabilities, compatible with complex industrial control systems, supporting various valve specifications and materials. The valve lifespan exceeds one million cycles, ensuring long-term reliable operation and reducing costs.

■High-Precision Feedback System

Maintains high detection sensitivity and stability even in complex environments, ensuring high precision and consistency in fluid handling.

■Easy Installation, Efficient Operation

Manual pull-down for rapid syringe replacement, foolproof design simplifies the installation process, with convenient dial settings and support for online upgrades to enhance operational efficiency.

■Compatible Instruction Set

Proprietary instruction set compatible with mainstream market products, providing broader application support.

■High-Performance Components, Improved Quality

Gold-plated connections, durable lead screws, and powerful motors enhance equipment lifespan, accuracy, and performance while operating at low noise levels for a comfortable operating experience.

■Flexible Configuration

Supports standalone use or cascading up to 15 pumps to adapt to various fluid handling requirements.

■Intelligent Limit Protection

Precisely monitors the operational range of the pump, preventing over-limit operations and providing safety assurance for the equipment.

Parameters

Line Speed Range: 0.005mm/s~25mm/s

Maximum Thrust: 10kgf

Maximum Stroke: 30mm

Stroke Control Precision: ≤1%

Stroke Resolution: 0.01mm/step

Number of Channels: 1

Operating Time Range: 1.2S-100min

Power Supply: DC24V±10%, current ≤ 1.5A.

Compatible Syringes: 50uL,100uL,250uL,500uL,1mL,2.5mL,5mL

Compatible Valves: Three-way valve, four-way valve, six-way valve, nine-way valve

Communication Interface: RS-232/RS-485,CAN

Shell Material: Aluminum Alloy

Programming Function: Task programmable and storable; syringe protection and blockage alarm, multiple installation methods, automatic switching of rotary valves, and higher flexibility for embedded installation; high precision control:Achieves automated high-precision and accuracy for fluid transmission, dilution, and distribution

Working Environment: 15℃~40℃, relative humidity <80%

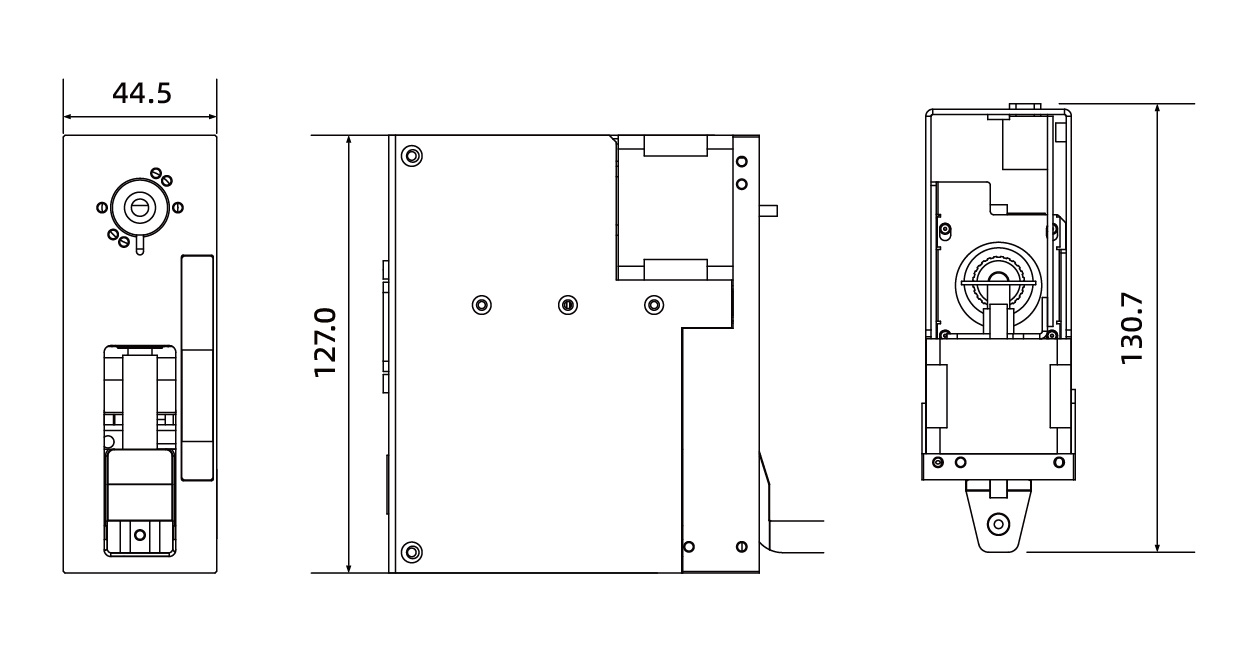

Dimensions (L×W×H): 130.7×44.5×127(mm)

Syringe Flow Rate Parameters

| Syringe Capacity | 50μL | 100μL | 250μL | 500μL | 1mL | 2.5mL | 5mL |

| Min flow rate(mL/min) | 0.0005 | 0.0010 | 0.0025 | 0.005 | 0.010 | 0.025 | 0.05 |

| Max flow rate(mL/min) | 2.5 | 5 | 12.5 | 25 | 50 | 125 | 250 |

Above flow parameters are obtained by using silicone tube to transfer pure water under normal temperature and pressure, in actually it is effected by specific factors such as pressure, medium, etc. Above for reference only.

Dimension(mm)

Application Fields:

Environmental, industrial, and scientific research scenarios, among many others.

Typical Applications:

Spray gold film applicator, liquid handling machine, water quality testing,

materials preparation, etc.